By harnessing the power of explainable artificial intelligence (XAI) software and the process safety skills of our human experts, we have created a HAZOP solution that digitises the entire process.

Less time – more efficiency – less risk

By using Kairos’ XAI-driven functional digital twin, our digital HAZOP reduces the time spent on HAZOP workshops, decreasing blind spots and increasing the overall quality by using the intelligent technology – with less support required from design, operational and safety experts.

Key features

- All guide words automatically covered

- Process library with FMEA

- Tree view shows failure (initiating event) propagation to consequence

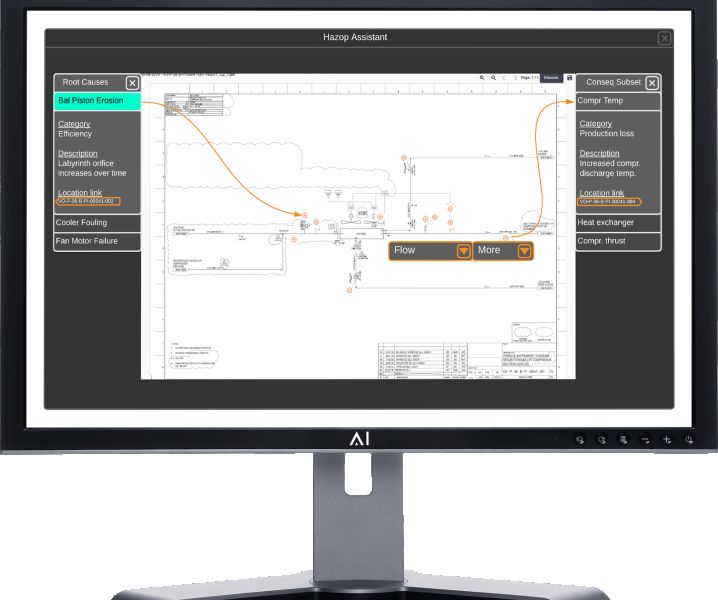

- P&ID view shows cause, deviations and consequence safeguards

- Analysis spans multiple systems - not just single nodes

- Enables plant wide HAZOP, re-HAZOP and modifications (MOC HAZOP)

- Toolbox for optimised design regarding number of sensors, actuators and safeguards

- HAZOP functional modes fully compatible with Control Room Assistant

Benefits

- Regularly updated HAZOP documentation

- Leverages learnings from incidents

- Increases quality of HAZOP

- Reduces time to re-HAZOP

- Less dependence on availability of experts

- Reduces blind spots

- Complete coverage of failure modes (FMEA)

- Operability covered with verification, mitigation and prevention tasks

- Includes alarm and trip coverage