Faster, more accurate HAZOP studies

Our digital HAZOP Assistant combines Vysus Group’s deep risk analysis expertise within high-hazard industries with Kairos Technology’s game-changing AI technology to digitalise the HAZOP process.

Better decision making, faster with explainable AI

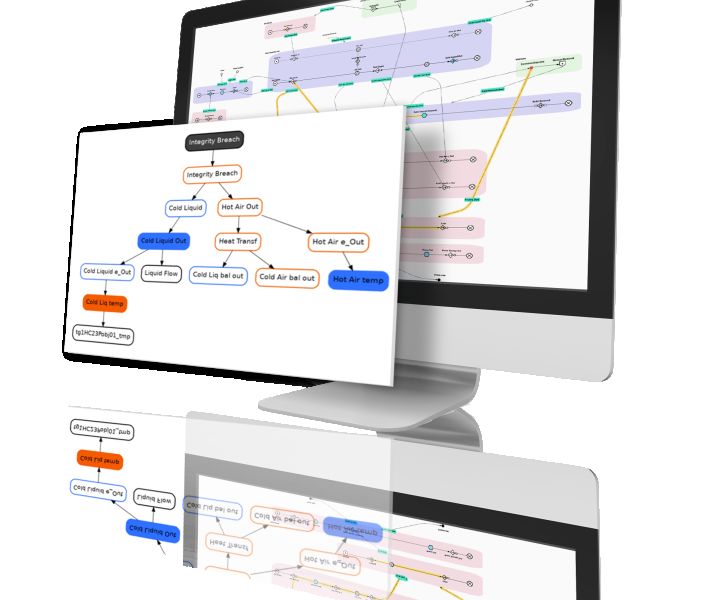

HAZOP Assistant creates a digital twin using existing P&IDs, traditional or smart. Combining explainable AI with functional modelling, HAZOP Assistant systematically evaluates potential hazards, ensuring a more consistent and objective analysis.

It can automatically test and analyse multiple process simulations and flag potential risks within seconds, rather than the hours or days human analysis would take.

The approach not only enhances the accuracy of the studies but also standardises the process, reducing the impact of human variability.

35%

35% reduction in HAZOP study time

70%

70% of risk scenarios identified before HAZOP workshop

Higher quality HAZOP reporting

HAZOPs play an essential role in identifying potential risks during industrial operations but the traditional approach relies heavily on human expertise and input, making studies time-consuming, expensive, disruptive to day-to-day operations and open to human error. HAZOP Assistant eliminates many of those hurdles.

Key benefits

- Reduces workshop time and resource requirement

- Automates repetitive tasks to save time

- Minimises human error

- Reduces dependence on the availability of experts

- Cuts travel-related carbon emissions

- Allows senior teams members to focus on more complex, high-risk processes

- Increases data accuracy and reduces analysis blind spots

- Provides repeatable, scalable process

- Ever-green study reduces time and cost of re-HAZOP and modifications (MOC HAZOP)

- Centralised data management with easy access to historical studies

- Benchmarks against anonymised industry data

- Update smartly during any upgrade or asset improvement work

Key Features

- Simple, intuitive design

- 70% of the HAZOP scenarios analysed prior to the workshop.

- Customisable for various industries

- Most guide words automatically covered

- Process library with FMEA

- Tree view shows failure (initiating event) propagation to consequence

- Visualisation of causes, deviations, and consequences on top of the P&IDs related.

- Analysis spans multiple systems - not just single nodes

- Toolbox for optimised design regarding number of sensors, actuators and safeguards

- HAZOP functional modes fully compatible with Control Room Assistant

- Easy integration with other safety management tools