Run your assets safely and cost effectively, with our risk-based approach to integrity and maintenance planning.

Overview

Today’s operations face ever-greater scrutiny of performance and risk metrics. We can help you drive productivity and profitability safely. You’ll benefit from deep asset management understanding across your equipment, people, processes and data, maintaining your asset integrity.

From the smallest pump to complex processes for plants and multiple facilities, we’ll consider your unique operating environment to realise asset value. Our advanced risk-based techniques will help you determine the probability and consequences of equipment failure, prioritise activities and optimise schedules.

20%

40%

Reduce operating costs by 40%.

Track record

We’ve supported oil and gas operations in the upstream, midstream and downstream sectors. This includes the asset integrity of wells, fixed and floating structures, floating production storage and offloading vessels (FPSOs), subsea and above-ground pipelines, land rigs and refineries, as well as chemical, petrochemical, renewables and power generation assets.

Our research and technology advancement initiatives have helped the renewable energy sector to grow. We’re committed to contributing to a low-carbon future while maintaining your asset integrity at its highest levels.

We’ve also provided solutions for a spectrum of other sectors, notably pharmaceutical and food and drink businesses.

Service breakdown

- Software consulting and engineering support for asset performance management (APM) and risk-based inspection (RBI)

- Mechanical asset integrity (MI) programme implementation (including RBI)

- Integrity management strategies/plan implementation and optimisation

- Process safety management (PSM) implementation and support

- Inspection optimisation and non-destructive examination

(NDT) consulting

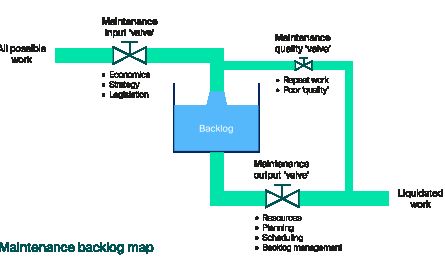

- Maintenance management optimisation

- Reliability improvement studies, planning and implementation

- Root cause analysis (RCA)

- Preventative maintenance (PM) optimisation studies

- Reliability centred maintenance (RCM)

- Failure mode effect and criticality analysis (FMECA)

- Spare-parts optimisation

Corrosion Consulting and Engineering

- Corrosion studies and consulting, including corrosion control documents (CCDs)

- Damage mechanism reviews (DMRs)

- Integrity operating window (IOW) solutions

- Materials engineering and fitness for service (FFS) assessments

- Failure and root cause analysis

Benefits

- Increase asset availability

- Avoid unplanned downtime

- Optimise maintenance and inspection schedules, with longer intervals between turnarounds

- Reduce lifecycle OPEX and CAPEX costs

- Use leading management systems compatible with ISO 55001

- Meet regulations and standards

- We work with a number of partners in implementing software solutions including, Metegrity, Inductosense, InServe Mechanical Integrity Group and Antea